I. Core Functions

1. Enhanced Corrosion Resistance

- Forms a dense wax film over the passivation layer, blocking penetration of corrosive agents (e.g., moisture, salt spray), significantly improving salt spray resistance.

- Compensates for the reduced protective properties of chromium-free passivation films in eco-friendly processes.

2. Improved Mechanical Protection

- Reduces surface friction coefficient (to 0.09–0.15), enhancing scratch/abrasion resistance during handling or packaging.

- Provides anti-blocking effects, preventing adhesion between stacked metal parts.

3. Optimized Surface Properties

- Increases coating slipperiness and improves tactile feel/appearance.

- Maintains surface smoothness and reduces fingerprint residue (used in fingerprint-resistant coatings).

II. Applications & Compatibility

1. Sealing for Zinc Plating Passivation

- Acts as a post-passivation sealer for galvanized layers, filling micro-cracks in chromate films to boost corrosion resistance by 7–10×.

- Widely used for fasteners (e.g., screws, nuts).

2. Acid System Compatibility

- Stable in acidic passivation systems containing chromium residues, preventing coating failure from ion reactions.

3. Light Metal Protection

- Compensates for performance gaps in chromium-free passivation of Al/Mg alloys via supplementary wax film protection.

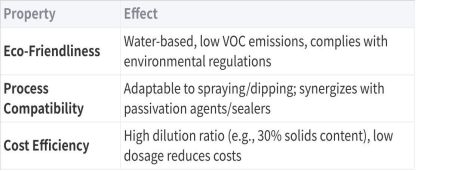

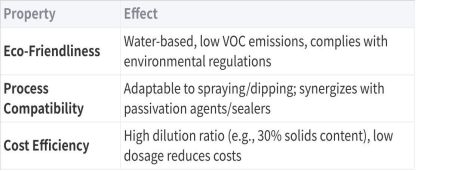

III. Technical Advantages

Contact Us :shanghai Vana Biotech Co., Ltd📍 Address: Room 203, Building 2, No.1588 Huhang Road, Shanghai, China🌐 Website:www.vanabio.com 📱 WhatsApp: Avery +86 15056351624