🔧 Key Functions of Wax Emulsion in Dacromet Coating

As a critical additive in Dacromet coating solutions (e.g., CT 3360), wax emulsion delivers three primary benefits:- Enhanced coating density: Fills micro-gaps between zinc/aluminum flakes, improving moisture barrier properties with salt spray resistance >1200 hours.

- Optimized surface properties: Reduces friction coefficient to 0.06–0.18, preventing thread adhesion during nut assembly, and improves coating uniformity and tactile feel.

- Environmental compatibility: Water-based system aligns with Dacromet's pollution-free profile, generating no wastewater or emissions.

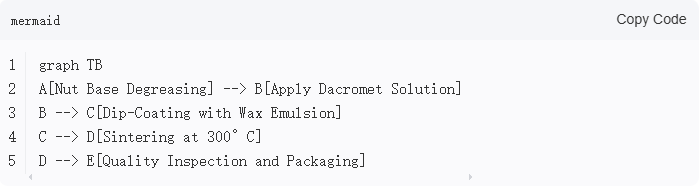

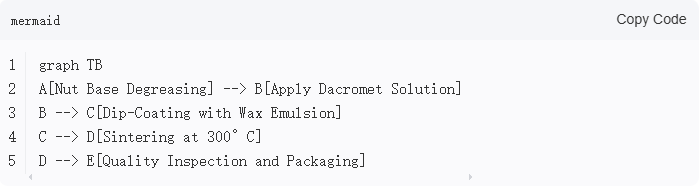

⚙️ Process Flow for Dacromet-Treated Nuts with Wax Emulsion

Critical Control Points:

- Coating ratio: Wax emulsion concentration at 1–3% to avoid reduced adhesion due to excess.

- Curing temperature: Maintain 290–310°C to ensure proper wax film formation and bonding.

⚖️ Core Advantages vs. Traditional Hot-Dip Galvanizing

Performance Indicator

| Dacromet with Wax Emulsion

| Hot-Dip Galvanizing

|

Corrosion Resistance

| >20 years (marine environments)

| 5–8 years

|

Thread Precision

| No secondary threading required (thin coating: 4–8μm)

| Needs hole enlargement/re-tapping

|

High-Temperature Stability

| Stable at ≤300°C

| Peeling at ~100°C

|

Environmental Impact

| Heavy metal-free process

| Acid-waste treatment mandatory

|

📌 Application Precautions

- Compatibility validation: Ensure wax emulsion compatibility with chromic acid passivators to prevent coating delamination (pre-testing recommended).

- Storage requirements: Store uncured coating solution in sealed, dark conditions to inhibit wax oxidation.

- Cost-benefit analysis: Higher upfront cost (~2× hot-dip galvanizing) offset by 40% lower lifecycle expenses.

💎 Summary

Wax emulsion significantly enhances Dacromet coating density and surface properties, extending nut corrosion life to >1200h salt spray resistance and improving assembly reliability, while preserving eco-friendly advantages as the top-tier alternative for premium fasteners.

Contact Us :shanghai Vana Biotech Co., Ltd

📍 Address: Room 203, Building 2, No.1588 Huhang Road, Shanghai, China

🌐 Website:www.vanabio.com

📱 WhatsApp: Avery +86 15056351624